direct drive vs belt drive motor

Theres also no belt residue and these fans cost less to maintain generally speaking because belts dont wear down and break. Direct drive pump.

The System Benefits Of Direct Drive The Comparison Tab Tv

Direct-drive vs belt-drive.

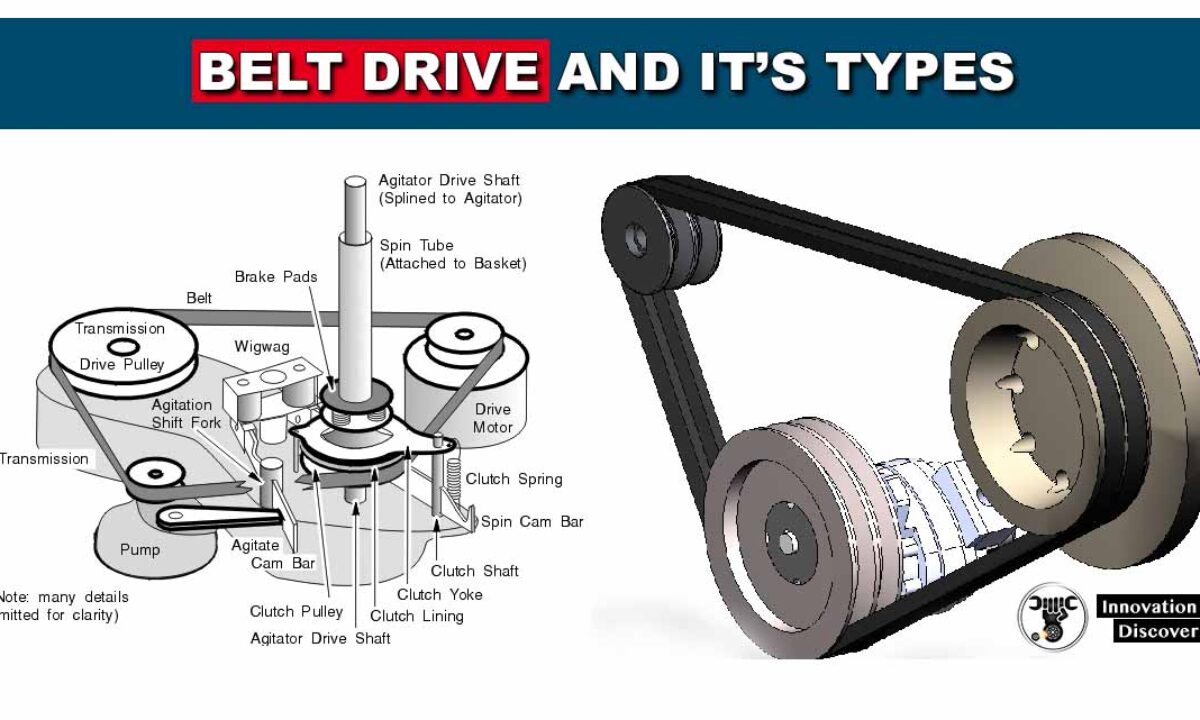

. This is the Arduino Code. Belt-drive motors consist of a pulley system that runs the motor while direct-drive motors use a single motor shaft with all of the power being sent through one winding which leads to more weight being transferred from the motor to the blades. Would I be able to run the drivers at a lower power setting if I used gearing.

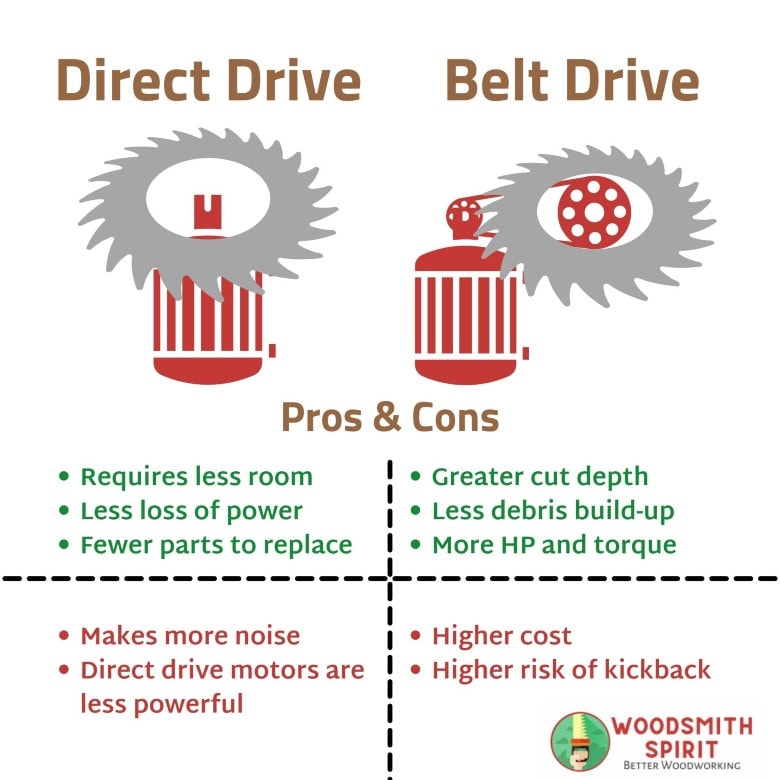

Even when belts are properly tensioned and the sheaves are aligned the power transmission loss of a belt drive fan. Direct drives requires less space in comparison to belt drives so smaller machines. Because of this there is far less wear and tear when compared to belt drive motors.

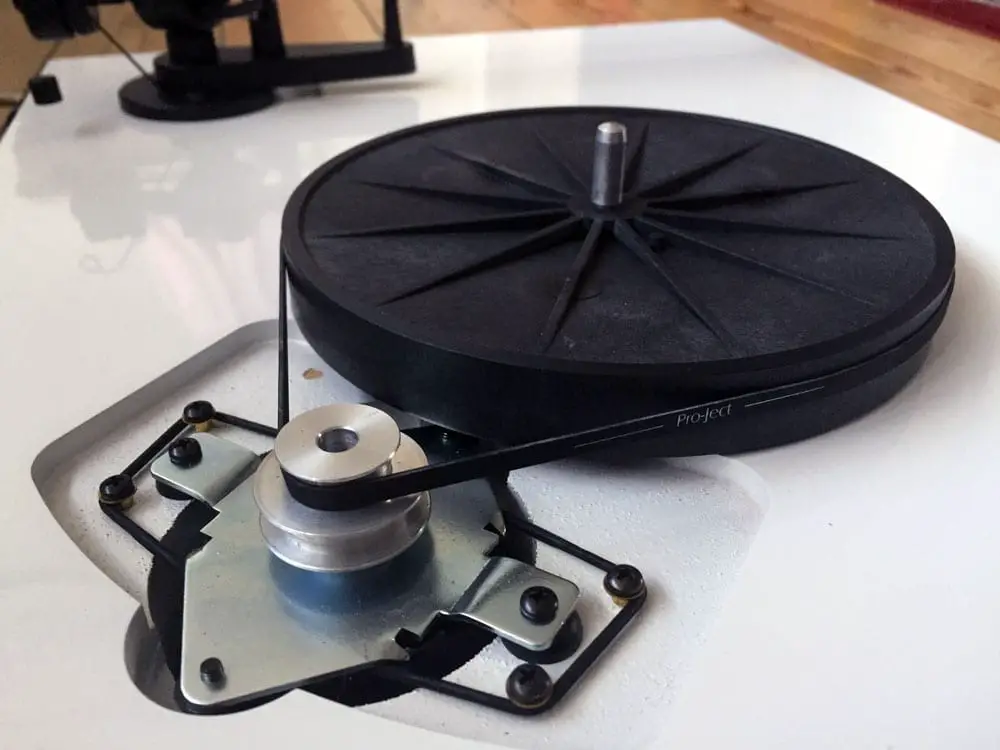

This kind of pump mounts directly on the motor or engine has few moving parts and is the most cost-effective option. The direct drive turntable meanwhile features a platter which is directly attached to the players motor. Both are created for different audiences.

They both are different in how the motor spins and their design differs from each other. Direct drive pumps are mechanically simpler than belt drive pumps. Belt drive elastic can wear down and it can eventually break.

With their extreme longevity direct-drive motors go longer without a repair. For instance a direct drive saw can only cut wood about two inches thick. In summary price and the fact that belt drive motors are not attached directly to the turntable are the two biggest differences.

However the bearings and other. Universal motors are noisy and require maintenance bearings and brushes Much lower HP rating never compare HP rating of. A direct-drive turntable on the other hand will skip the belt bit and feature a.

Due to the simplicity of direct drive pumps the design is more compact which is useful when used in tight areas. Unlike belt driven fans theres less energy loss because theres a reduced amount of friction as the fan operates. The obvious advantage of direct drive is simplicity.

Of course belts themselves have plus. Belt drive washing machines are mostly appreciated for their budget-friendly prices. Assuming speed reduction a direct drive low speed motor will have a lower efficiency lower power factor bigger size and higher cost as compared to belt driven higher speed motor.

Direct drive fans have no power transmission loss since the propeller is directly connected to the motor shaft. The second most distinct difference between the two is price. When it comes to belt vs.

Belt drives apply greater load on the main shaft of the machine it has a direct effect on the life time of bearings shaft misalignment and as a result oil leakage and more vibrations. Additionally theyre easier to clean. As direct drive washers are more efficient in their function they remain the top choice for manufacturers in.

As you might have guessed the primary difference between a direct drive motor and a belt drive motor is that the former does not utilize a belt. However broken parts will require a technician with training which can be challenging to find. Check out my gear on Kit.

Direct-drive turntable remember this is not the same as a belt-drive turntable with a motor connected to the platter with a belt. Belt drive motors are a less costly alternative to direct drive. The motor function of the direct drive is different from the belt drive.

The Direct Drive Turntable. A direct drive turntable features quick start-up times slightly more consistent speed and stronger torque. They can absorb significant amounts of shock and vibration and eliminating the need of gearboxes speed and torque shifts are made possible by adjusting the size of the pulleys in the belt drive system.

Here a direct drive washer is 38 costlier than a belt-drive model. If the pulley loosens it. Direct-drive tables also will give you a speed control so as a DJ if you want to change the tempo to blend one song into another with two turntables it is pretty easy to do so with the range of speed adjustment available on a direct-drive table.

A direct-drive automatic turntable has a motor located directly under the platter and it rotates using the bearing. However belt drive saws also require more maintenance because of the multiple working parts. However a belt drive fan has power transmission loss due to the friction between the belt and sheaves and due to the drive shaft bearings.

Although the initial cost is high if you keep the washing machine for a couple of years then the extra cost can be recovered easily. Belt-drive turntables by contrast usually take several seconds to get up to speed. Nonetheless the reason behind the increasing costs is not just direct-drive motor technology.

A belt drive uses an induction motor no brushes. Would a geared or belt drive help reduce the vibration in the mechanism. For instance the belt will need to be changed and parts need oiled.

But if you are tight on budget then a belt drive-based washing machine is the only option. In a direct drive motor it is a universal motor such as all hand tools have and they have brushes. In the simplest terms possible the difference between a belt-drive and a direct-drive machine can be derived from their respective names.

The difference between belt drive and direct drive is simple. Video of the machine running. The next easiest options are belt drive or a geared stepper motor.

Motors in belt drive applications can experience significantly different. Direct drive washing machines do not have any moving parts in the motor. Direct drive is definitely better in terms of noise wash performance and power consumption.

Greater efficiency is the biggest pro of direct drive fan configurations. The direct drive is mainly created for the DJs and designed to work with two turntables while the belt drive doesnt possess such functions. We discuss positives and negatives for eac.

A belt-drive has a platter that sits on a bearing and is driven by a pulley-style belt usually made of rubber.

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

Direct Drive Vs Belt Vs Gear Racing Wheels Which Should You Buy

Direct Drive Vs Belt Vs Gear Racing Wheels Which Should You Buy

Direct Drive Vs Belt Drive Washing Machine Which Is Better Kitchenarena

Table Saw Motor Drive Types And Specs Explained Guide

Direct Drive Vs Belt Drive Turntables What S The Difference Sound Matters

Belt Drive Vs Direct Drive Laundry Youtube

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

Direct Drive Vs Belt Drive Washing Machine Which Is Better Kitchenarena

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

Types Of Belt Drive Material Applications Advantages Disadvantages Engineering Learn

Chain Drive Vs Belt Drive Vs Shaft Drive Motorcycle Drivetrain Explained

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

Direct Drive Vs Belt Drive Washing Machine Which Is Better Kitchenarena

Difference Between Direct Drive And Belt Drive Washing Machine Youtube

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

Direct Drive Vs Belt Vs Gear Racing Wheels Which Should You Buy

Direct Drive Vs Belt Vs Gear Racing Wheels Which Should You Buy